BIM for Offshore Platforms: Enhancing Safety and Efficiency in Harsh Environments

Understanding BIM Technology in Offshore Applications

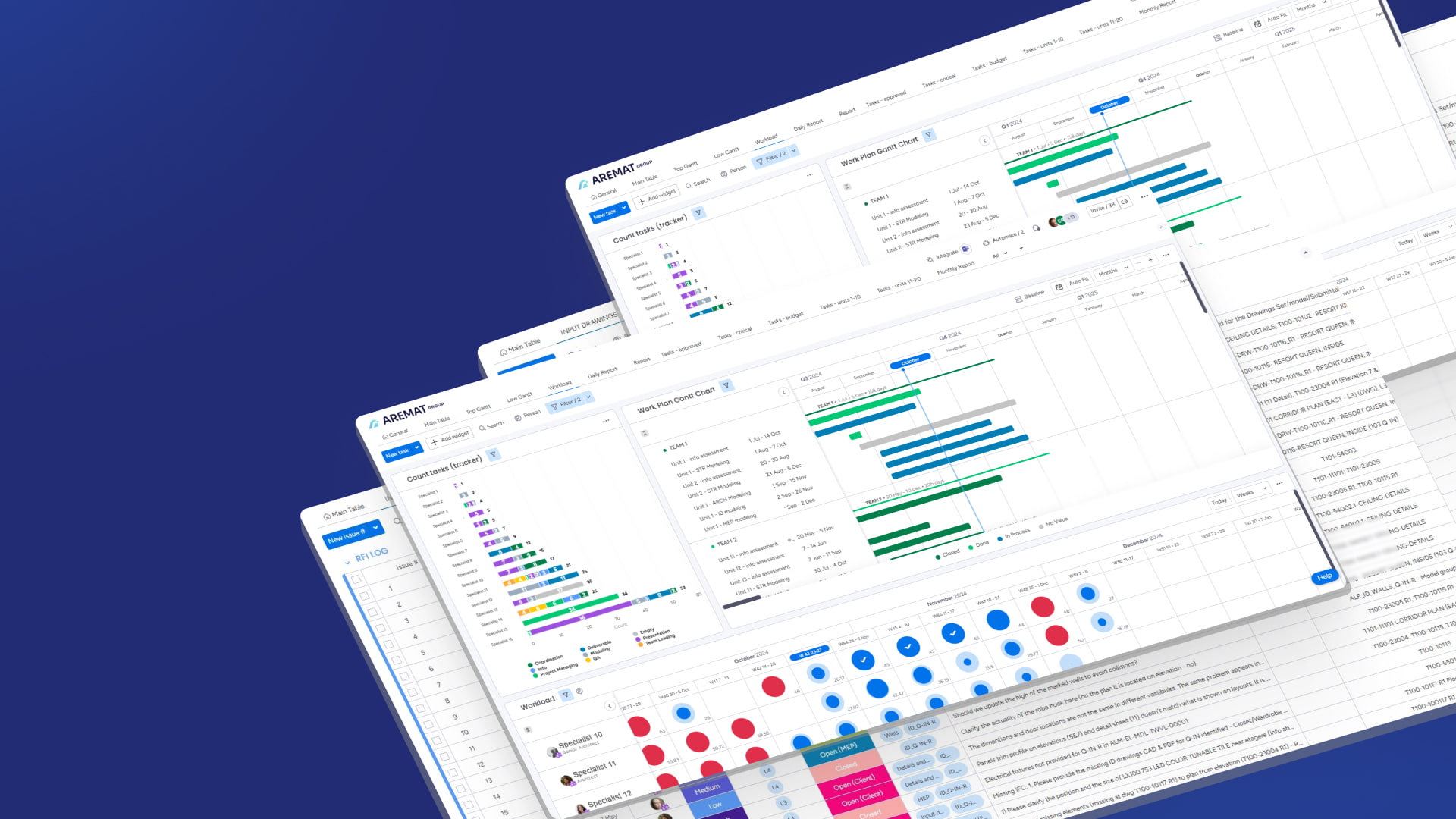

Explore Our Case Studies

Explore Our Case Studies

Building Information Modeling has evolved from a simple design tool into a comprehensive project management technology that integrates all project data into intelligent 3D models. For offshore platforms, this means every component, system, and operational parameter can be visualized, analyzed, and optimized before physical construction begins. The offshore industry increasingly recognizes BIM's potential to address persistent challenges including cost overruns, schedule delays, and safety concerns. With oil price volatility driving efficiency demands, offshore operators are adopting construction industry best practices, with BIM leading the transformation.

Key Benefits of BIM for Offshore Platform Development

- Seamless information sharing between international project teams

- Real-time coordination between engineering, procurement, and construction phases

- Improved stakeholder communication across complex project hierarchies

- Advanced clash detection preventing costly installation conflicts

- Virtual safety training environments using platform-specific scenarios

- Emergency response planning with accurate 3D evacuation route modeling

- Precise material quantity calculations reducing waste and logistics costs

- Optimized maintenance scheduling through integrated asset management

- Enhanced facility management capabilities for long-term operations

- Significant reduction in human errors and design inconsistencies

- Improved project visualization enabling better decision-making

- Greater accuracy in cost estimation and schedule planning

Addressing Critical Industry Challenges

- Inaccurate project estimates and scope definition

- Design and coordination errors

- Unforeseen project changes and modifications

- Administrative and communication breakdowns

- Unrealistic time and resource planning