The Future of Gas Infrastructure: How BIM is Reshaping Pipeline Projects

Optimization of Gas Pipeline Design

- Enhanced Visualization: A detailed digital model incorporates all pipeline components, including pipes, valves, sensors, and pressure control systems, allowing engineers to analyze layouts comprehensively.

- Clash Detection & Conflict Resolution: BIM identifies potential clashes with other underground utilities, transportation networks, or natural obstacles, ensuring conflicts are addressed before construction begins.

- Simulated Performance Analysis: BIM-powered simulations assess mechanical and hydraulic loads, optimizing pipe diameter, wall thickness, and material selection to enhance structural integrity and minimize risk.

Improvement of Gas Pipeline Construction

- Precise Installation Drawings: Detailed 3D models generate highly accurate construction drawings, reducing human errors and enhancing the speed of on-site execution.

- Supply Chain Optimization: BIM automates material quantity take-offs, ensuring procurement aligns precisely with project needs and avoiding costly over-purchasing or delays.

- Improved Coordination: Engineers, contractors, and suppliers collaborate within a unified digital ecosystem, facilitating seamless communication and issue resolution.

Enhancing Pipeline Monitoring and Lifecycle Management

- Real-Time Monitoring: Integration with IoT sensors enables continuous tracking of pressure levels, temperature fluctuations, and potential leak points within the pipeline system.

- Predictive Maintenance: Historical data stored within the BIM model helps forecast maintenance needs, reducing unexpected failures and extending pipeline longevity.

- Data-Driven Decision-Making: Asset managers can access a centralized database containing maintenance records, performance analytics, and compliance documentation for better operational planning.

Strengthening Safety Measures in Gas Infrastructure

- Compliance Validation: Models can be tested against regulatory requirements, ensuring adherence to international safety standards.

- Emergency Scenario Simulations: BIM allows operators to model and analyze potential risks such as gas leaks, pressure surges, and explosion hazards, leading to improved emergency preparedness.

- Evacuation & Access Planning: 3D models help design emergency evacuation routes and identify optimal access points for first responders in case of an incident.

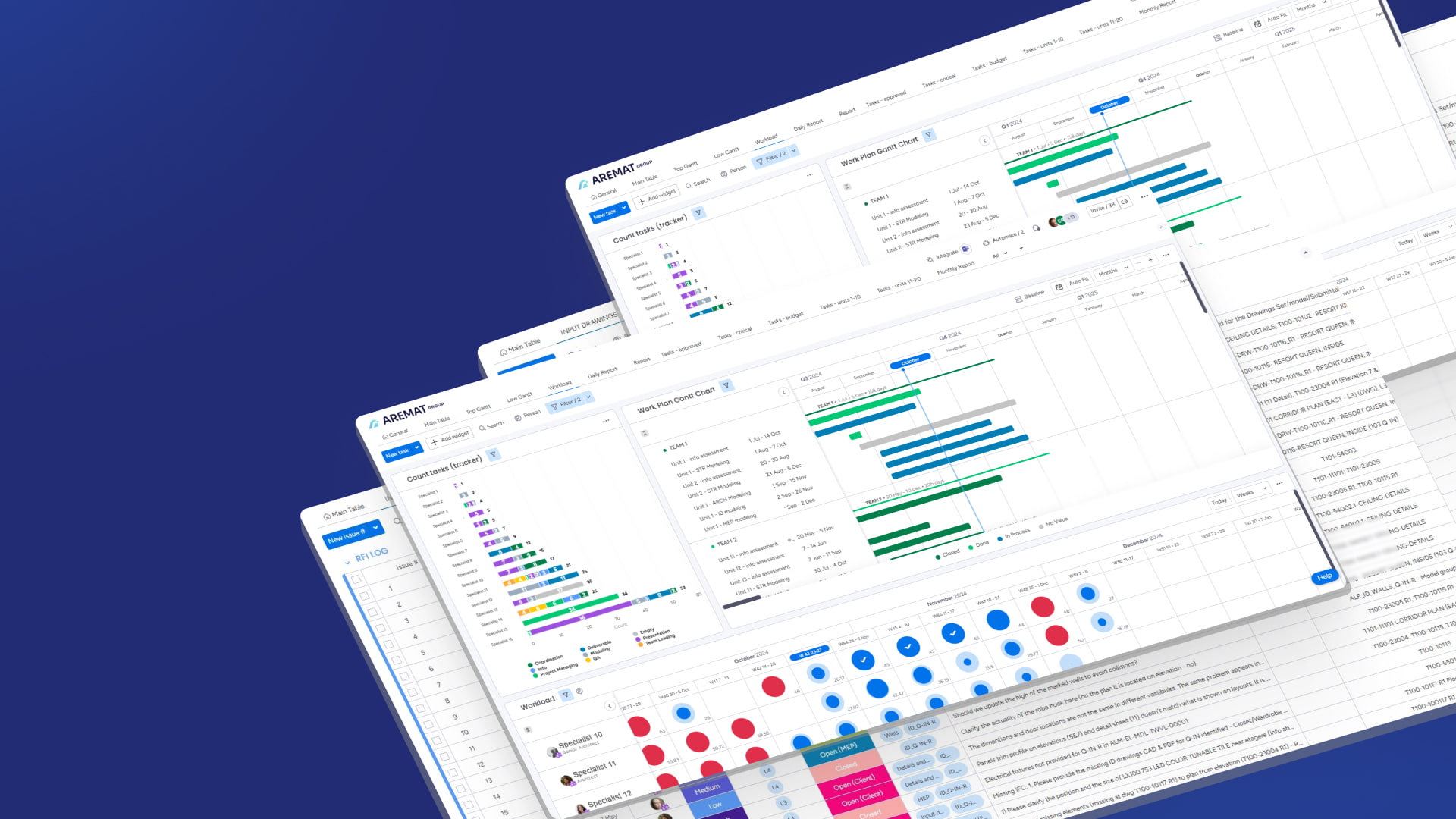

Improvement of Communication and Collaboration Among Project Participants

- Centralized Data Repository: All project participants, work with a single, unified, up-to-date model, avoiding misunderstandings and addressing technical issues promptly, reducing inconsistencies and ensuring alignment across disciplines.

- Interdisciplinary Coordination: Architects, engineers, environmental specialists, and construction teams collaborate in real time, preventing conflicts between structural, mechanical, and electrical systems

- Regulatory Transparency: Digital documentation ensures compliance with safety and environmental standards, simplifying the approval process with governing bodies.

Why BIM is a Must-Have for Gas Infrastructure Projects

Explore Our Gas Case Studies

Explore Our Gas Case Studies

By implementing BIM early in your gas project, you can avoid costly rework, increase coordination across teams, and ensure your infrastructure meets evolving industry standards.

Let’s build a more resilient energy future – together. We Plan, We Lead, You Build.

FAQ about BIM for Pipeline Projects

➡️ Talk to AREMAT Group about cost-optimized BIM implementation.

➡️ Let AREMAT Group support your permitting process with expert BIM modeling.

✅ Improved visualization

✅ Structural optimization

✅ Conflict detection before construction

➡️ AREMAT Group can deliver custom BIM design for your pipeline.

👉 Contact us to discuss your gas pipeline project today.